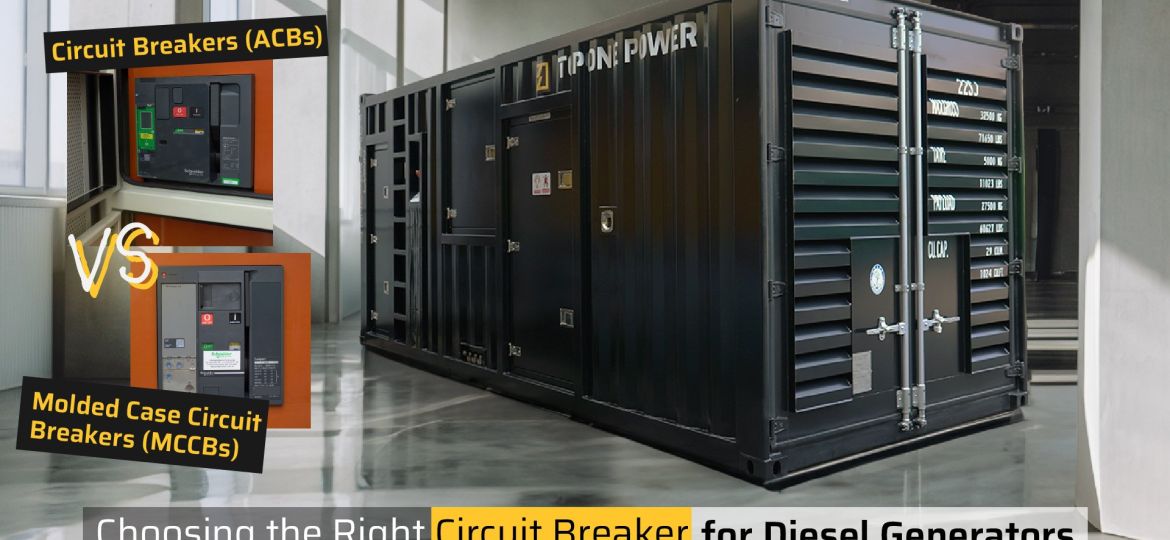

When safeguarding your diesel generator and ensuring its reliable operation, selecting the appropriate circuit breaker is paramount. We understand the importance of quality components, which is why we often integrate components from trusted manufacturers like Schneider Electric. Air Circuit Breakers (ACBs) and Molded Case Circuit Breakers (MCCBs) are two common types, each suited to specific applications. This article will break down their differences, explore key factors influencing your choice, and explain how Top One Power helps you simplify the process.

ACB vs. MCCB: Key Considerations

Circuit breakers prevent overloads and short circuits. Key considerations for selection include:

- Current Rating: For example, Schneider Electric’s ACBs handle up to 6300 A for large systems, while their MCCBs support up to 3200 A for smaller setups.

- Ultimate Breaking Capacity (kA): Essential for handling short-circuit currents safely. When current ratings overlap (e.g., 630A to 3200A), it’s crucial to ensure the breaking capacity is adequate. For example, in Hong Kong, both ACBs and MCCBs can be designed to achieve a 40kA capacity to meet local standards. In such cases, the final choice might hinge on other following factors.

- Cost and Space: MCCBs are budget-friendly and compact, while ACBs, though larger and more expensive, deliver enhanced capabilities.

- Short-Circuit Protection: ACBs provide superior defence against high fault currents; MCCBs offer adequate protection for standard needs.

- Application Suitability: ACBs thrive in industrial heavy-duty settings; MCCBs fit simpler, space-constrained projects.

Real-World Applications & Our Bonus Feature

For projects at 1600 A or below, we often recommend MCCBs for their cost-effectiveness and compact design. While MCCBs are frequently used, we have also seen clients opt for ACBs even when MCCBs would technically suffice. For instance, in a 1000kVA Cummins KTA38-G5 diesel generator enclosure project, the client chose an ACB for enhanced protection.

Our Bonus Feature: Streamlining Operation with Smart Terminal Placement

In our diesel generator container designs, we go beyond standard configurations to provide solutions that enhance usability and efficiency. Our thoughtfully designed diesel generator containers feature a separated control panel room and circuit breaker room. This unique design offers significant advantages:

- Simplified Operation: We place the customer input/output terminals in the circuit breaker room. This strategic placement eliminates the need for technicians to repeatedly travel back and forth to the control panel room, saving time and improving convenience.

- Enhanced Control: Because the customer input/output terminals are separate from the control panel, operations on these connections do not require access to or interfere with the main control system. This reduces the risk of accidental disruption or damage to critical control functions.

- Easy Maintenance: Additionally, we provide the option to implement an N-link feature for 3-pole breakers, delivering the functionality of a 4-pole breaker for easier disconnection during maintenance.

Let Us Simplify Your Decision

ACBs excel in high-power, critical applications, while MCCBs are ideal for smaller, cost-effective setups. We integrate high-quality components from Schneider Electric and other client-preferred brands. In addition to component selection, we offer designs like our containers with separated control panel and circuit breaker rooms, which streamline operation. When the choice isn’t clear, contact our expert team today for a free consultation!